A photographic record of the construction of a NEW chassis and substructures of an Austin Healey 3000.

This particular vehicle will be a useable “Rally Replica” for the road using some alloy panels within the substructures, modified LH Pedal Box to accommodate tripple carburettors, larger adjustable rear dampers and the omission of rear seat pans. All modifications will be done in a “period” style. This project is to showcase the workmanship and fit of the panels produced by Dave Hardwick Engineering.

Although this is a slightly modified vehicle a standard or more radical Healey can be constructed to suit the customers requirements.

Chassis Extensions and welding fixture

Suspension tower struts and welding fixture

Main floors with reiforcement plates

Inner sills and floors welded in position

Front bulkhead centre section positioned

Centre section welded in position

Outer footwell side in position

Hinge panel and reinforcing panel “gripped” in position

Crossbrace assembly position checked with the original front shroud

Rear bulkhead centre section positioned

Trial assembly

Trial assembly

Checked with rear shroud

“B” Post

“B” Post

Hood mount

Hood mount

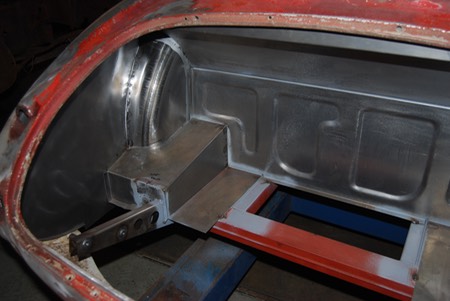

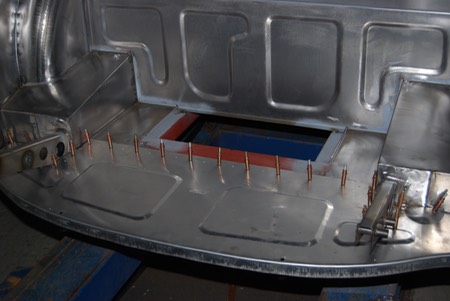

Aluminium boot floor and landing plates welded to rear cross member

Boot floor held in position prior to riveting

Front Aluminium arch and mounting plates

Aluminium arch

Both front arches in position

DAS 10 Damper and New Mounts

Front cross brace and arches in position

Alloy scuttle top in position

Strengthened Engine mounts.

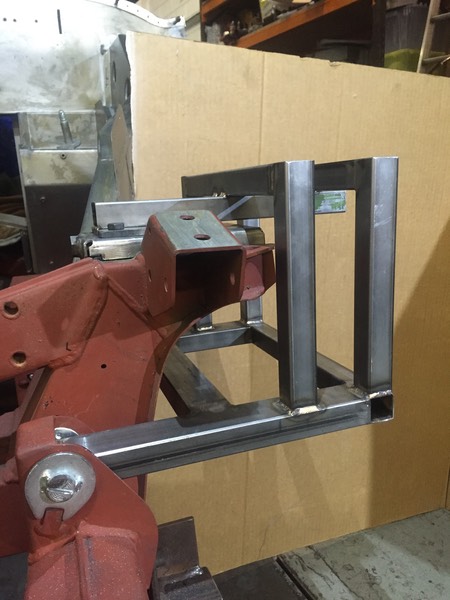

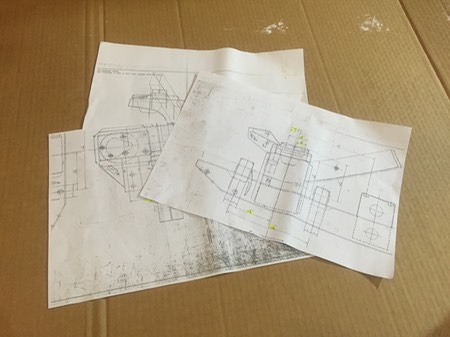

Adjustable Damper mounts fitted with the aid of a fixture manufactured from original drawings.

Original panels trial fitted and Shroud put back to the correct shape, also the shroud has been shaped to suit the Grille Surround.

New alloy wing !!!!!

Not Good !!!

The poorly shaped and positioned sidelight platform has been flattened out and my press tool clamped in position.

The finished result.

The rear wings are not that impressive!

A certain amount of reshaping the top wing line is required to make it straight.